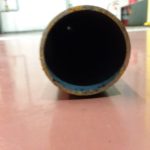

Recently GCAP and North Point changed out a leaking tube on our hand-on training Kewanee Fire Tube machine. The was a great learning and educational experience for some of our instructors and interns. Firetube boilers can come in different sizes and configurations; therefore, it is difficult to list a common set of problems.

Water leaks are always a possibility, especially with older boilers where corrosion may have been occurring for several years. The firetubes will be the thinnest material in the entire boiler and if corrosion (either fireside or waterside)is very aggressive, they will show signs of leakage. This is easily detected if the inspector sees water in the furnace or any other fireside space.If there is poor or no water treatment, sediment can accumulate enough to plug the spaces between the tubes in extreme cases. Just as with the furnace, this condition can lead to overheated and damaged tubes.

The fireside of the tubes can also be subject to scale and deposit build-up when the boiler is fired with oil or solid fuel. This adversely affects boiler efficiency and can cause the tubes to overheat.Tube ends that are projecting beyond the tube sheet more than the Code allows can overheat and crack. If the tubes are attached to the tube sheet by welding, cracks in the tube ends can propagate to the tube sheet, and possibly run into the ligaments between the tubes. A tube sheet can easily be damaged beyond repair with cracks of this nature, and it can start with a fraction of an inch in excess tube projection.