The Garden City Ammonia Program’s Boiler Division’s recent trip to Hutchinson Kansas, home of Superior Boiler Works Inc. provided an opportunity for observing the building of boilers from start to finish. Steve Rucker, the Director of the Boiler Division, and Jim Burnette, the Lead Boiler Instructor for the division received a tour of the manufacturing facility by Kevin Dean, Combustion and Controls manager, and Danny Lane, the Director of Production Operations. During the tour, we were shown the full scope of what it takes to build a boiler from the ground up. We saw flat plate steel rolled and welded into a boiler shell, tube sheets being installed, Morrison tubes being corrugated and installed, tubes being installed, refractory being installed, finished product being heat treated and prepped for paint.

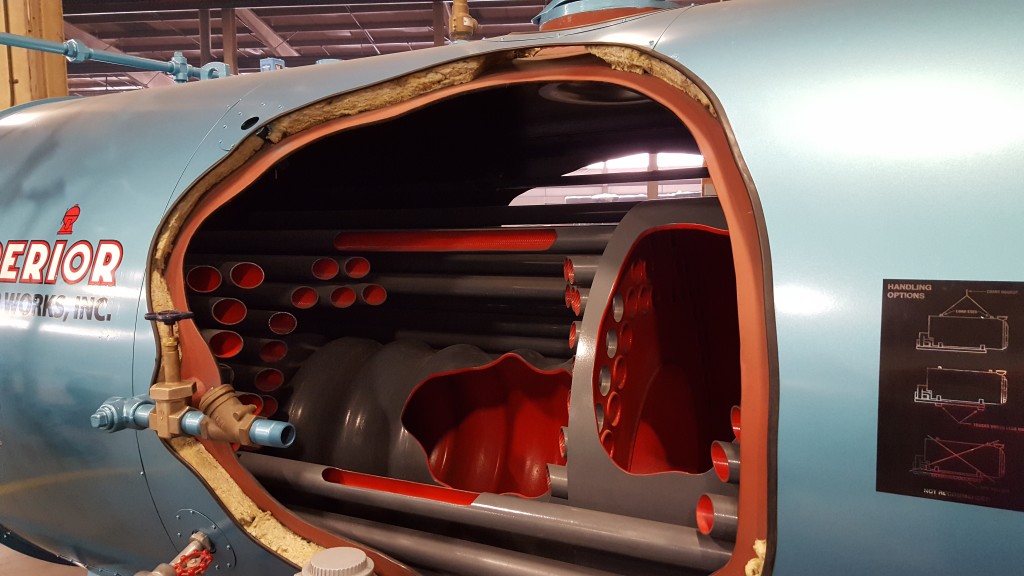

There were several boilers on the floor in different stages of construction and being trimmed out and fitted with different burners. We saw everything from a 2200 HP firetube boiler being built, to a 1000 HP portable boiler room on wheels. The portable boiler room was fitted with a D.A. tank, feed pumps, stack, and everything you would need to produce steam. All you have to do is hook up a water supply, main steam line, fuel supply, and put the stack on and you were ready to start making steam. They have some cut away display models that were very cool. If you’ve never been on a tour of a boiler manufacturing facility, it was really something to see. We had a great time and appreciate the hospitality of Superior Boiler Works Inc. management team.